Transfer automation

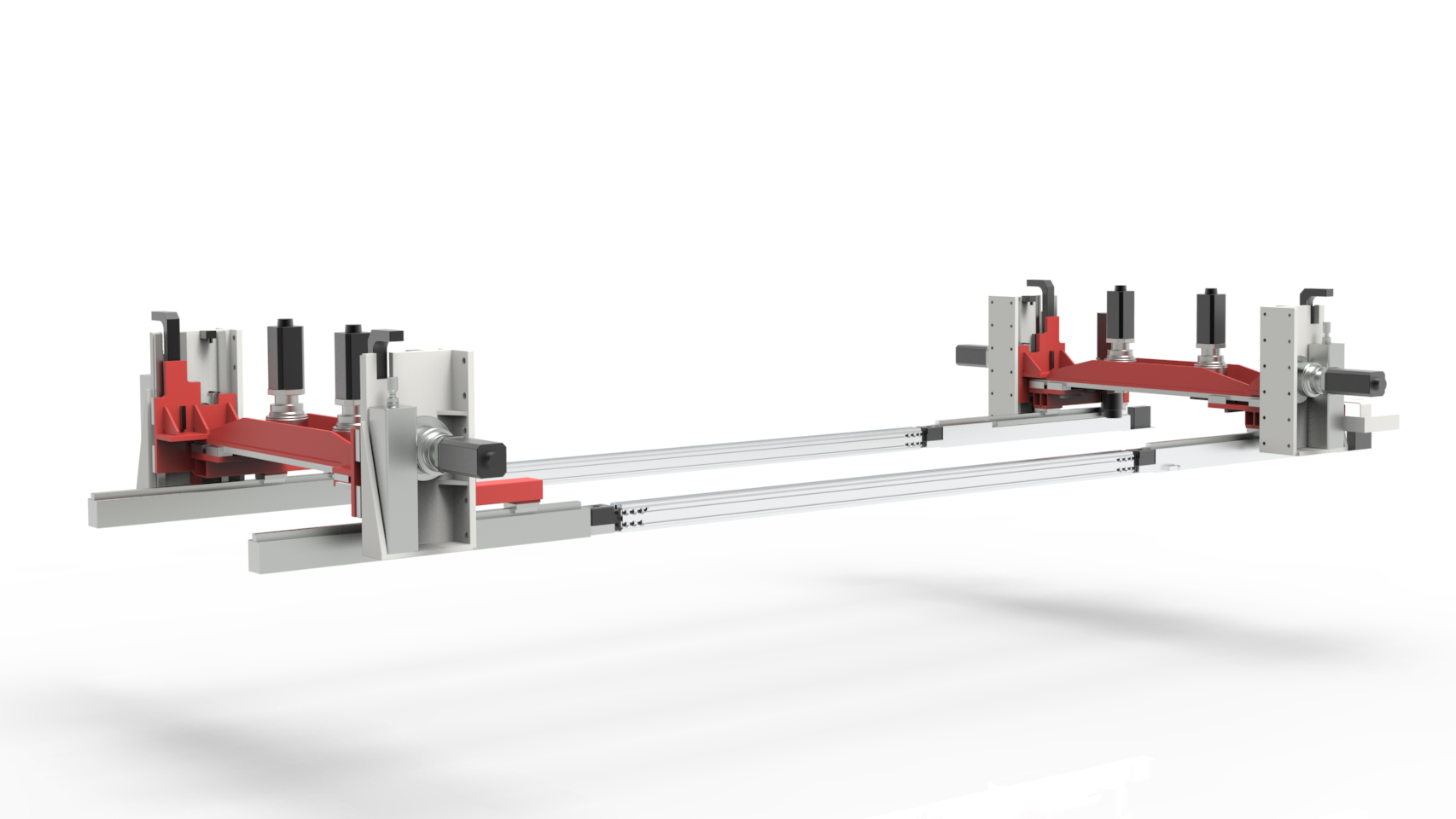

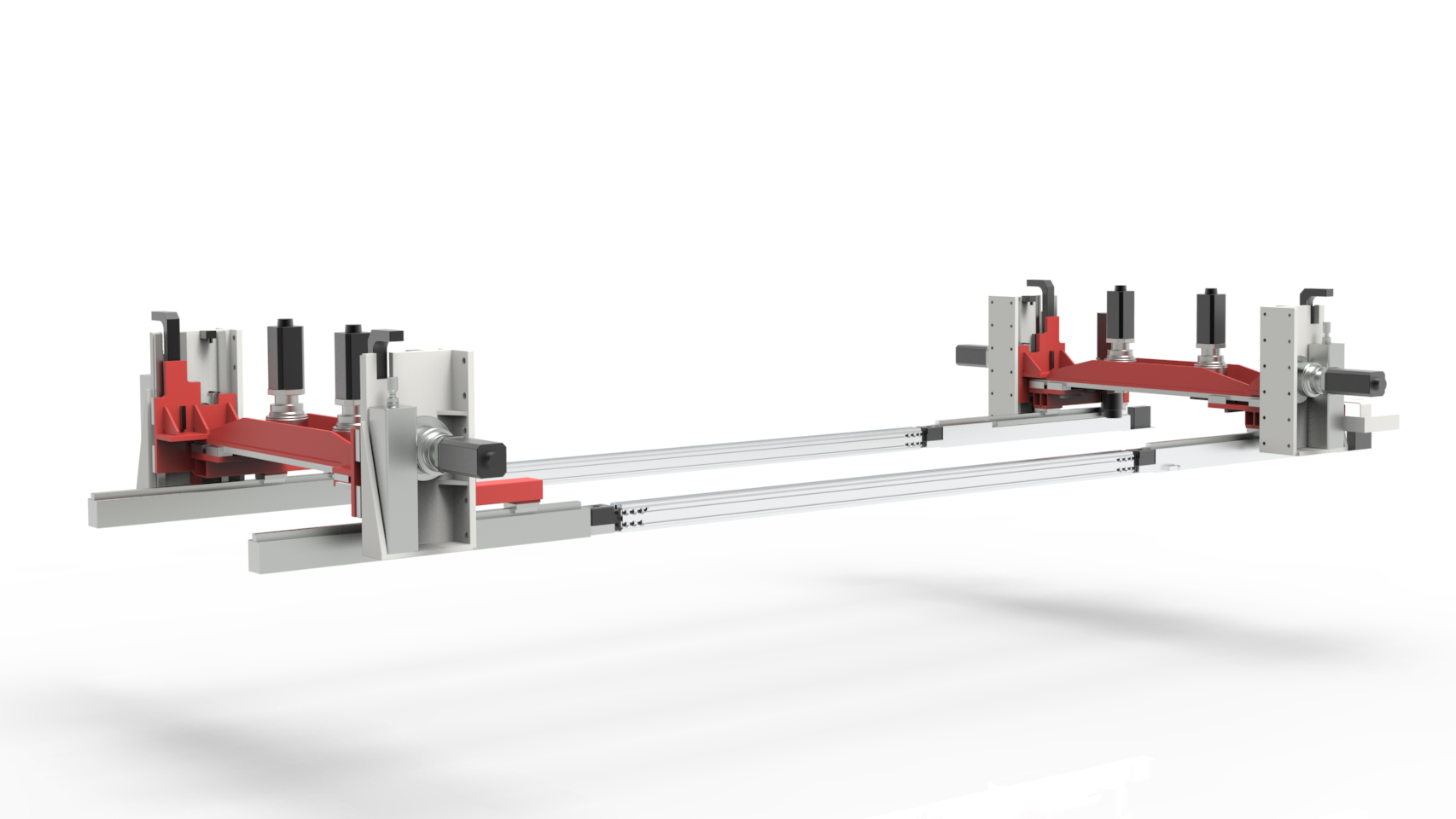

ProMotion M

Our transfer automation ProMotion is suitable for all applications in sheet metal forming. With its various sizes, the transfer automation can be used for all press fabricates and all press types (e. g. eccentric press, link drive press, hydraulic press and servo press).

Technical data

Table length

min. 3,200 mm - max. 4,100 mm

Feeding motion

min. 0 mm - max. 1,000 mm

Closing motion

min. 0 mm - max. 200 mm

Lifting motion

min. -30 mm - max. 350 mm

Dimention transfer bar

length 100 mm x height 150 mm

Transport weight

100 kg

Closing-Lifting Unit

Specification

- Closing-lifting unit at press inlet side

- Closing-lifting-feeding unit at press outlet side

- Asymmetric motion sequences possible

- Vibration-optimized, mechanical

Options

- Closing motion adaptable to press window

Transfer Bars

Specification

- 1 set transfer exchange bars

- Manuel transfer bars coupling

Options

- 2 sets transfer exchange bars

- Automatic transfer bars coupling

- Transfer exchange bar racks

Technology Packages

Specification

- Transport and part monitoring control one-sided

- Static electronic overload protection

Options

- Transport and part monitoring control two-sided

- Special transfer motions

- Adaptive electronic overload protection

- Electronic vibration compensation

Control & Visualization

Specification

- PLC-System Siemens S7

- Drive unit Sinamics

- Safety via Safety Integrated

- Teleservice

- Control panel TP 1500

- Visualization with WinCC-Comfort (TIA-Portal)

- Synoptic automatic operation and tool changes

Your Contact Partner

Marc-Andy Luippold

Senior Sales Manager

- +49 7454 881-501

- +49 7454 881-11

- m.luippold@dreher.de

Your direct Line to DREHER Automation

Haben Sie Fragen oder dürfen wir Sie beraten? Nutzen Sie unser Anfrageformular – wir freuen uns über Ihr Interesse.