Electric Lamination Stamping

DREHER Automation is your Partner for the highly productive Manufacturing of Rotor and Stator Laminations

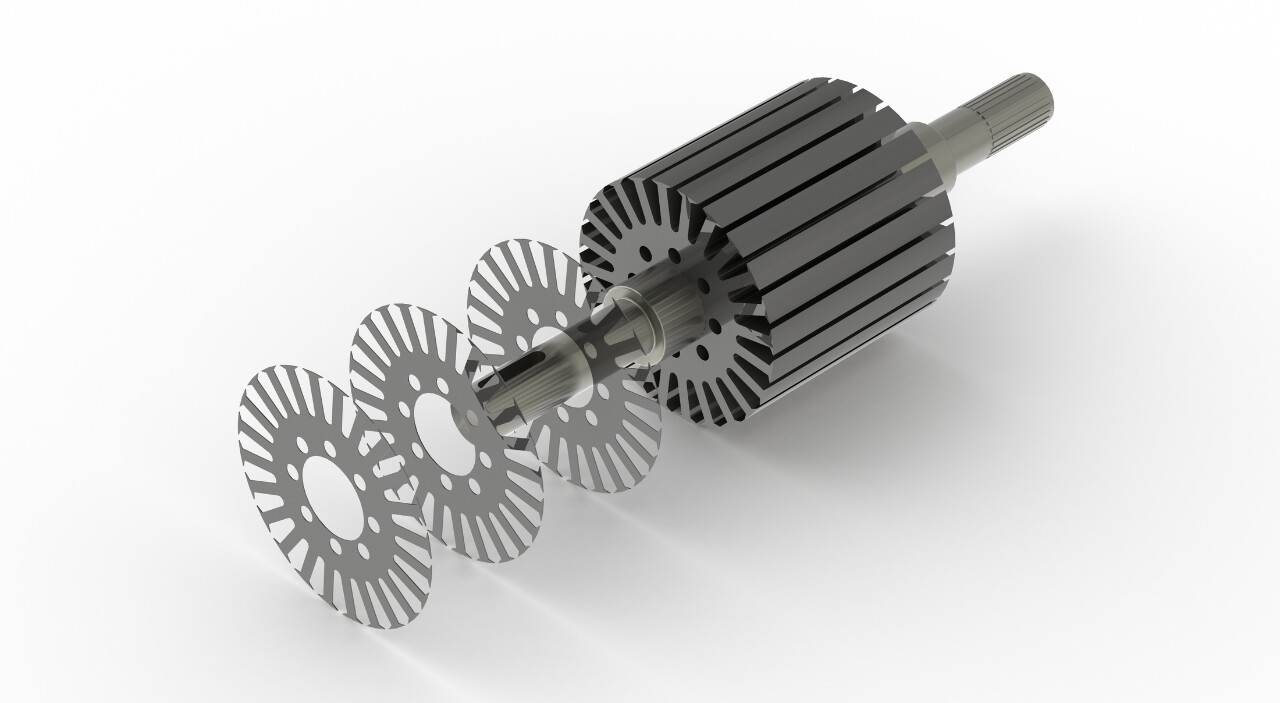

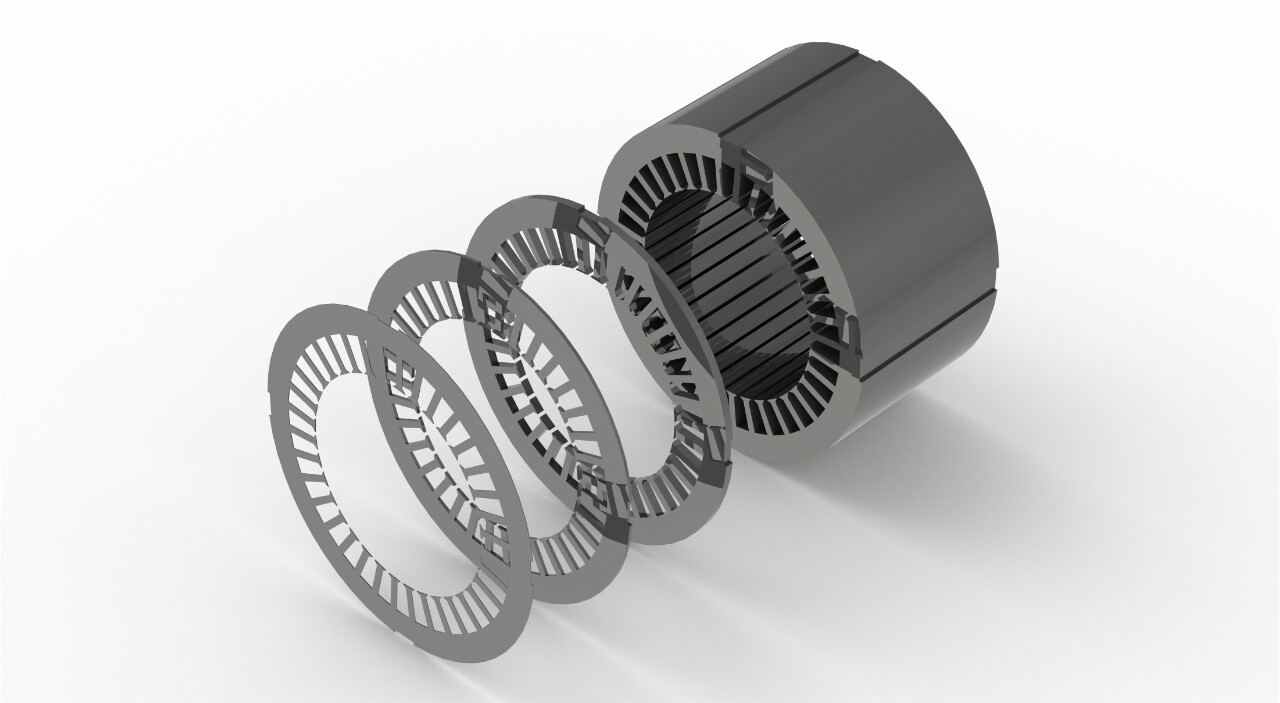

Driven by the transformation, the global market for electric laminations has developed rapidly in recent years. In particular, the growing interest in solutions in the field of electromobility is leading to a steady increase in demand for rotor and stator laminations for the production of electric motors. At the same time, driven by the energy transition, the demand for generators in which rotors and stators are also used is also increasing.

In order to survive in this growth market, innovative manufacturing solutions are required that guarantee efficient, high-quality and economically attractive production at high volumes. In order to simplify the complex process requirements in the field of electric lamination manufacturing for you, DREHER Automation has developed turnkey solutions from a single source together with competent partners.

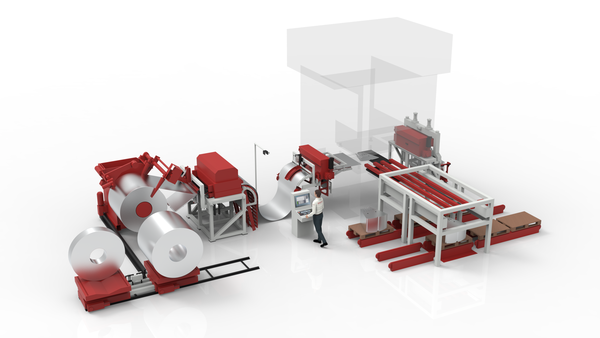

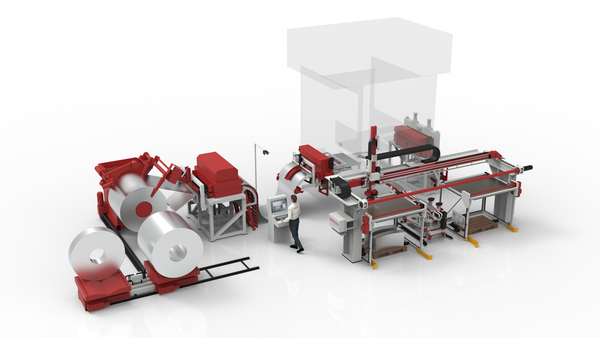

High-Speed Stamping & Packaging Press Line for the Production of Rotor and Stator Packs

Our high-speed stamping and packaging press line for the production of smaller rotors and stators made of electrical sheet metal, especially for the production of electric motors, is a turnkey solution from two competent partners, ZEULENRODA Pressentechnik and DREHER Automation. The fast-running press with integrated press automation and tool technology stamps and packs rotor and stator laminations fully automatically at up to 200 rpm.

The joint co-operative approach therefore optimally combines the specific press expertise of ZEULENRODA Pressentechnik with mechanically and electrically integrated press automation from DREHER Automation. This offers clear advantages for rotor and stator manufacturers:

- Application-optimized fast-running forming press with integrated press automation optimized for the application

- Consistently integrated hardware and software solution with Siemens

- Short delivery times thanks to a high degree of standardization

- High-performance service with around 40 employees at two locations in Germany

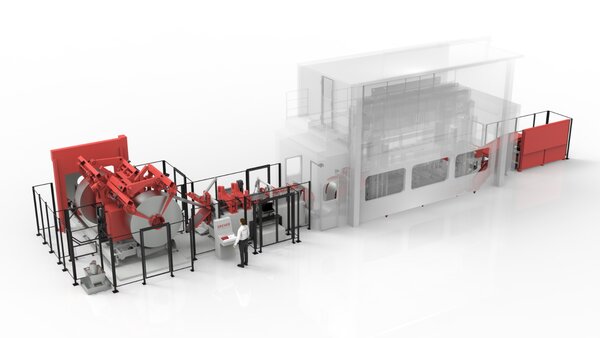

Highly productive Stamping & Packaging of Rotor and Stator Segments

For large generators in particular, it is necessary to produce rotor and stator laminations in segments. DREHER Automation also offers customized and highly efficient turnkey solutions for this application with competent press partners. We can produce single segments at up to 40 rpm and rotor and stator segment packages at up to 200 rpm with our electric lamination stamping presses.

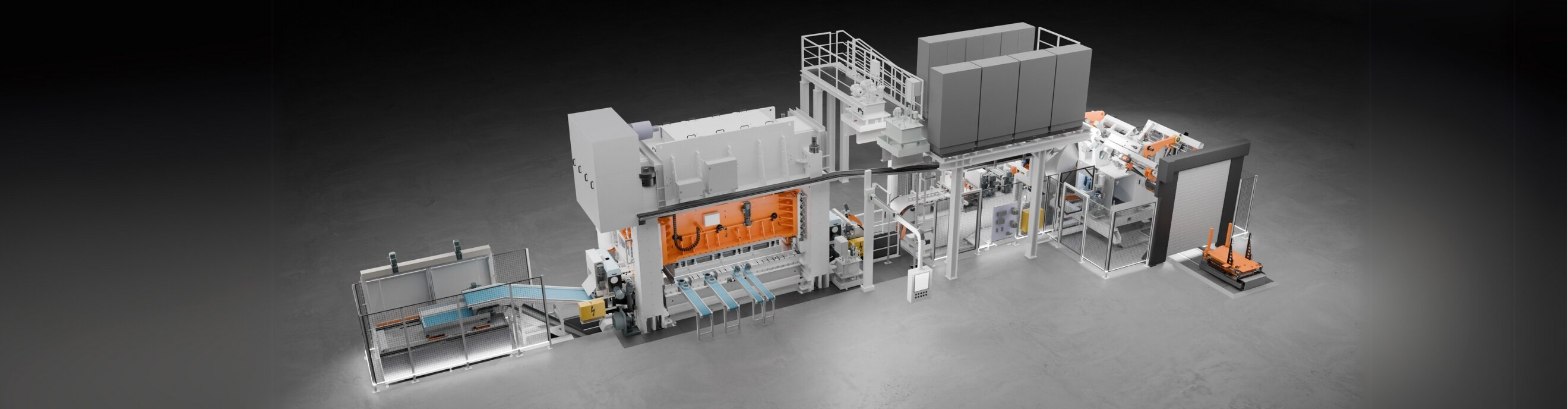

Integrated Control Concept with Siemens Components

DREHER Automation has developed a integrated control concept based on Siemens components for these handling tasks. In close cooperation with Siemens, this has resulted in an integrated overall system control for the forming press, press automation, tool and peripherals. It consists of the SIMATIC S7 motion control system with integrated safety functions, converters from the Sinamics S120 family and the latest generation of energy-efficient servomotors from the 1FK series.

Furthermore, we at DREHER Automation are aware of the productivity-enhancing influence of user-friendly and self-explanatory operation and visualization. For this reason, our system visualization is carried out via SIMATIC WinCC (TIA Portal) on large touch panels at central locations. In addition, synoptics for automatic operation and sequence synoptics for coil and tool changes are of course obligatory.

The durability of our systems is well-known in the branch. We also ensure this through our excellent after-sales service. For “just-in-time” support, all our systems have remote maintenance access, among other things.

Your Contact Partner

Steffen Priebs

Senior Sales Manager

- +49 7454 881-503

- +49 7454 881-11

- s.priebs@dreher.de

Ihr direkter Draht zu DREHER Automation

Haben Sie Fragen oder dürfen wir Sie beraten? Nutzen Sie unser Anfrageformular, indem Sie es über die Schaltfläche ausklappen.