Blankine Lines

DREHER Automation keeps always an Eye on your entire Blanking Process

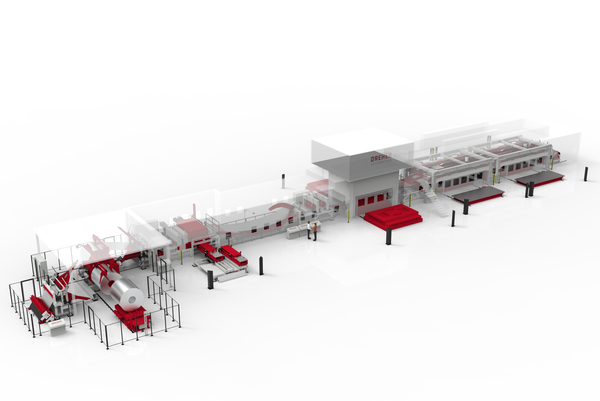

Blanking line, the combination of a strip processing line, a cutting machine (blanking press, laser cell or cut-to-length shear), and a blank stacker, forms the basis of every large pressing plant. However, using a blanking line can also be profitable for smaller pressing plants.

By decoupling the blanking and forming process, more space is created at your forming press for other processes or you can reduce the force of the forming press. You also gain the possibility of minimizing your material requirements thanks to optimal material utilization while at the same time considerably increasing the flexibility of your production process. At the same time, the high output capacity of our blanking line enables you to operate several forming processes simultaneously. Cost savings are even feasible if you are able to cut your blanks in your own press workshop and no longer have to purchase additional blanks.

We always have an overview of the entire process from the coil to the stacked blank. Regardless of whether you need longitudinal, trapezoidal, or contour cutting, we can supply the right solution for your production process.

Blanking - Cut-to-length Shear versus Laser Cell versus Blanking Press

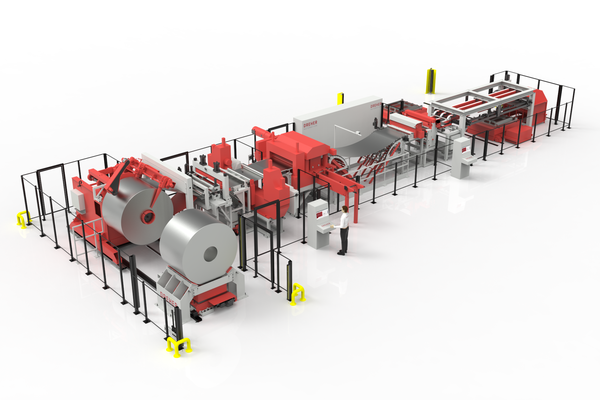

Depending on the application, we offer our customers blanking lines either with cut-to-length shear, laser cell or a blanking press. DREHER Automation always supplies blanking lines with cut-to-length shear or laser cell as complete systems solutions from a single source. With a cut-to-length shear you can cut blanks very cost-effectively. Particularly for rectangular blanks, but also for trapezoidal or shaped cuts, a blanking line with cut-to-length shear offers an excellent price/performance ratio.

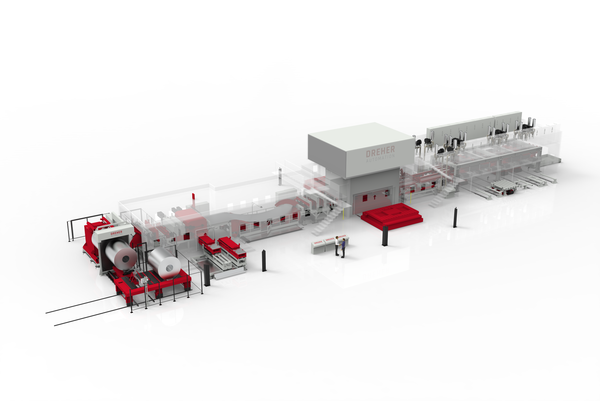

If, however, your production focus is on flexibility and the highly efficient blanking of form blanks, then a blanking line with a laser cell or a blanking press is recommended. Eccentric presses, toggle presses, or highly dynamic servo presses are particularly suitable for the blanking process. Our competent project management team will be happy to assist you in choosing the right press partner.

DREHER Automation Blanking Lines

With DREHER Automation's blanking lines, you can cut and stack your blanks made from steel, aluminum, or other materials fully automatically, with precise positioning and a high number of cycles at any time.

Our blank blanking lines are suitable for

- All materials (magnetic and non-magnetic materials),

- All strength ranges (universal, medium, and high strength), and

- All common blank shapes (e.g. rectangular blanks, circular blanks, or form blanks)

We supply blanking lines with

- Cut-to-length shear

- Laser cell

- Blanking press

The following blanking processes are possible

- Longitudinal or diagonal cut with cut-to-length shears

- Trapezoidal cut with swivel shears or swiveling cutting tool in a blanking press

- Form cut with faser laser

- Form cut with pre-formed cutting edge or blanking tool in a blanking press

We offer the most varied and individually adaptable stacking concepts

- Stacking of single, double, or multiple blanks on one stacking position, optionally with uninterrupted operation and a second stacking position

- Discharge of double or multiple blanks to two different stacking positions

The perfect Automation Concept for your Blanking Line

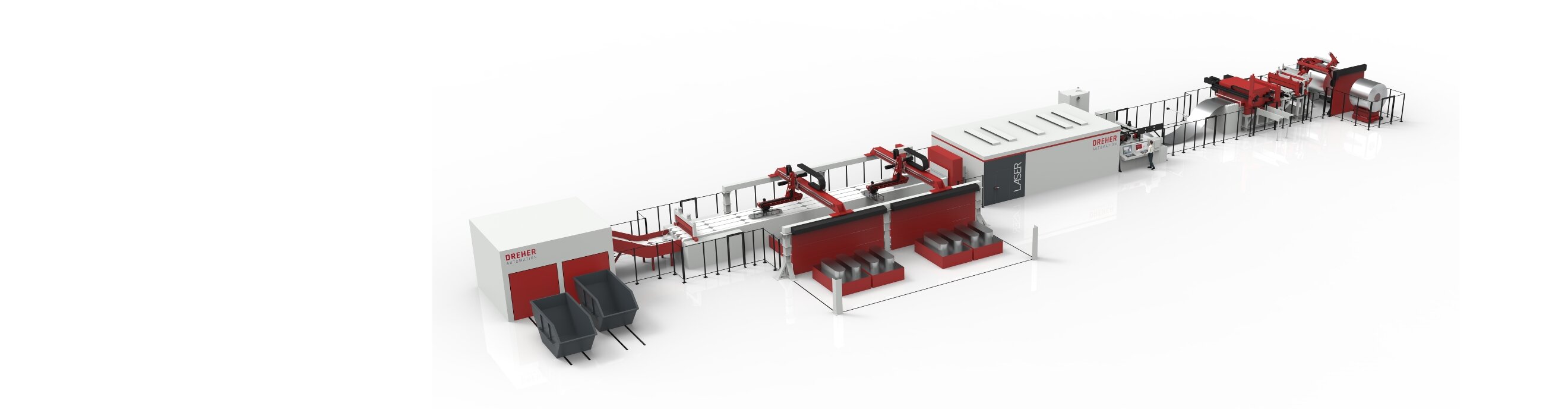

The level of automation of our blanking lines is always variable and individually adaptable to customer requirements. We supply the right solution for your production. In doing so, not only can you choose whether you want to operate the automatic functions in jog mode on sight, semi-automatically, or fully automatically. You can also integrate additional processes, such as strip start and strip end trimming. If necessary, it is even possible to process aluminum and steel on a blanking line.

Consistent integrated Control Concept using Siemens Components

DREHER Automation has developed a consistent control concept based on Siemens components for various handling tasks. This has resulted in an integrated automation solution in close cooperation with Siemens. It consists of the Simotion D motion control system, inverters from the Sinamics S120 family and the latest generation of energy-efficient servo motors from the 1FK series.

Furthermore, at DREHER Automation we appreciate the productivity-enhancing advantages of user-friendly and self-explanatory operation and visualization. For this reason, our system visualization is realized on spacious touch panels at a central location via WinnCC (TIA portal). Synoptics for automatic operation and sequence synoptics for coil or tool changes are mandatory for all our customers.

Our systems are renowned in the industry for their longevity. This is also guaranteed by our excellent After Sales Service. For “just-in-time support”, all our systems are equipped with remote maintenance access.

Your Contact Partner

Seref Varli

Sales Manager

- +49 7454 881-553

- +49 7454 881-11

- s.varli@dreher.de

Your direct line to DREHER Automation

Do you have any questions or would you like us to advise you? Simply fill out our contact form, we look forward to hearing from you.